Bottom Unheading Valves

Coke Drum Bottom Unheading Valve

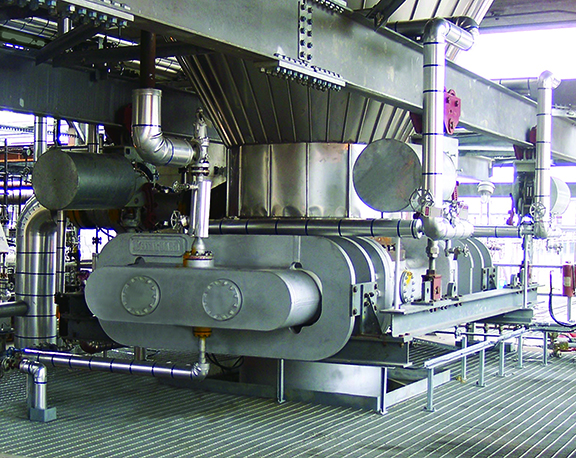

DeltaValve’s bottom unheading valve permanently connects to the coke drum, creating a totally enclosed system from the coke drum to the discharge pit. Utilizing patented dynamic seat technology, the device is tight-sealing, robust, and highly reliable. With the push of a single button from a remote location, safe and reliable unheading can be achieved. The valve is inherently safe, easy to operate, and designed to be maintenance free between turnarounds.

Key Advantages

- Proven technology

- Safe and reliable

- Low maintenance

- Part of a totally enclosed system

- Double block and purge

- Steam purged

- Single button operation

Physical/Technical Attributes

Bottom Unheading Valve

| Design | Per ASME section VIII Div.1,2 |

|---|---|

| Construction | Valve body: cast Bonnets: cast or fabricated |

| Metallurgy | Valve body: ASME SA217 Gr. C5 Bonnets: ASME SA387 Gr22 (fabricated) Bonnets: ASME SA217 GrWC9 (cast) |

| Dimensions | 357”L x 98”W x 40” H 21.6” face to face |

| Weight | 66,000 – 74,000 (depending on actuator) |

| Actuation | Single-ram hydraulics Auxiliary hydraulic override Electronic planetary roller screw |

| Interlocks / Controls / HPU | Engineered to plant specifications |

| Positive Lockout | Removable lock-out pin |

| Transition Spool | Engineered to plant specifications |

| Discharge Chute | Engineered to plant specifications |

| Purge Media | Steam |

| Drum Flange | 60 inch (1524 mm) standard |

| Shut-off | Double block and purge with 100% verifiable positive isolation |

| Pressure Rating | 154 psig (10.8kgf/cm2g) @ 940oF (505oC) |