11-06-2012

Rotork flow control technologies specified for UAE petroleum storage expansion project

The project at the Emarat Fujairah Terminal has included the construction of ten new storage tanks, increasing the site’s total capacity from 50,000 to 260,000 cubic metres. The facility is designed for the storage and distribution of gas oil, petrol and jet fuel to meet the growing regional demand for trading and bunkering. The design of the new tanks complies with the highest criteria for safety, employing control systems in accordance with international standards.

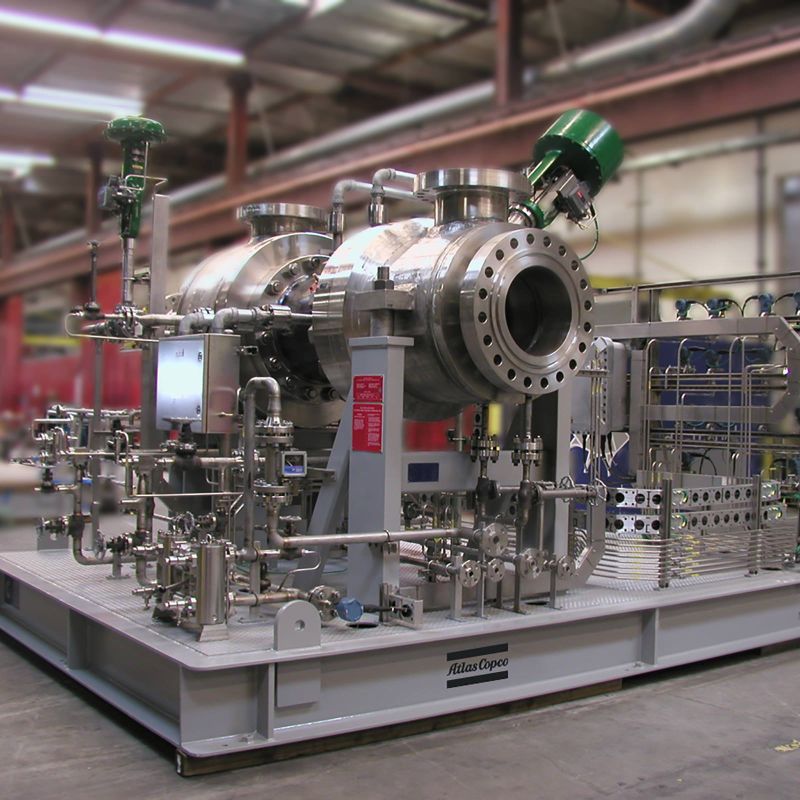

Rotork valve actuation technologies make an important contribution to the successful achievement of the control and safety standards. More than one hundred Rotork IQ explosionproof intelligent electric actuators with Rotork Pakscan two-wire digital control have been installed for the majority of valve duties.

Designed for maximum reliability with enhanced functionality, IQ actuators feature non-intrusive, intrinsically safe commissioning, data-logging and predictive maintenance capabilities. Reliability is enhanced by the double-sealed IP68 watertight enclosure, whilst the ability to download and diagnose operating data enables effective asset management to be planned and implemented with the minimum interruption to plant operations.

The Pakscan two-wire digital control system was specified by Emarat and the engineering consultant Penspen for its proven reliability and flexibility for valve control in the tank farm industry. Pakscan is designed specifically for valve actuators and the spacious environments associated with tank farm installations. The Pakscan configuration provides built-in redundancy from the valve to the control room, ensuring the security of vital control command and monitoring data. In addition, data from actuator data-loggers can be downloaded over the Pakscan network for diagnostics and analysis, enabling this vital function to be performed without leaving the control room.

Rotork EH electro-hydraulic actuators provide reliable failsafe valve management for safety related and emergency shutdown (ESD) duties. Utilising Rotork IQ intelligent actuation technology and designed to SIL3 standards for safety critical applications, EH actuators can be programmed for failsafe to open, failsafe to close or lock in position on power failure or ESD signal.

For the Fujairah Terminal project the Rotork actuators were fitted to valves at a local valve company and shipped to site as factory tested motorised valve (MOV) packages. Rotork’s Middle East office and UAE agent in Abu Dhabi are providing on-site and workshop support for the installed products.

The Fujairah Terminal is owned by the Emirates General Petroleum Corporation (Emarat). Main Contractor for the expansion project was Tata of India, with Albanna Engineering of Dubai responsible for the MOV installations. Systems integration has been performed by the Jebel Ali office of Larsen and Toubro.

News Category:

-

John Crane unveils Type 8628VL mechanical seal

John Crane has launched the Type 8628VL, a next generation mechanical seal engineered to solve the oil and gas industry's toughest challenges: maintaining sealing integrity ...

09-09-2025

-

Clariant to supply catalyst to the world's largest electric steam methane reformer

Clariant, a sustainability-focused specialty chemical company, today announced a supply agreement with SYPOX to manufacture and deliver catalysts for what will be the ...

09-09-2025

-

Worley receive FEED verification contract for renewable diesel and aviation fuel project

Worley has been awarded a contract by Preem for Front-End Engineering Design (FEED) verification for the planned conversion of the ICR plant at the Lysekil refinery in ...

08-09-2025

-

Honeywell to optimise production at AMIGO LNG export terminal in Mexico

Honeywell today announced that its modular liquefied natural gas pretreatment technology and Integrated Control and Safety Systems (ICSS) will be adopted at AMIGO LNG ...

01-09-2025

-

Covestro selects EnviNOx® technology for its Baytown site

thyssenkrupp Uhde has successfully delivered and commissioned its proprietary EnviNOx® technology to Covestro’s Baytown, Texas, facility. The advanced emission control ...

01-09-2025

-

REZEL Catalysts Corporation, a leading global catalyst manufacturer and licensor, and Aramco, one of the world's leading integrated energy and chemicals companies, announced ...

26-08-2025

-

Wood to provide project management consultancy services on Turkey's largest polypropylene plant

Wood, a global leader in consulting and engineering, is providing project management consultancy (PMC) services to develop Turkey's largest polypropylene plant and associated ...

21-08-2025

-

thyssenkrupp Uhde completes Pre-FEED for the Portland renewable fuels project

thyssenkrupp Uhde has completed the Pre-FEED phase for the Portland Renewable Fuels Project in collaboration with HAMR Energy. The project, located in Victoria, Australia, ...

21-08-2025

-

Accelerating the Demonstration Project for Its New Technology Contributing to the Petrochemical Industry’s Effort to Switch to Alternative Feedstocks Sumitomo ...

20-08-2025

-

Vioneo selects Lummus as its Polypropylene partner for a new grassroots plant in Antwerp

Lummus Technology, a global provider of process technologies and value-driven energy solutions, announced Vioneo has selected its Novolen® polypropylene (PP) technology ...

19-08-2025