27-01-2014

Hyperion Simulation to supply the OTS system for IGC Carbon Monoxide Plant to SIPCHEM

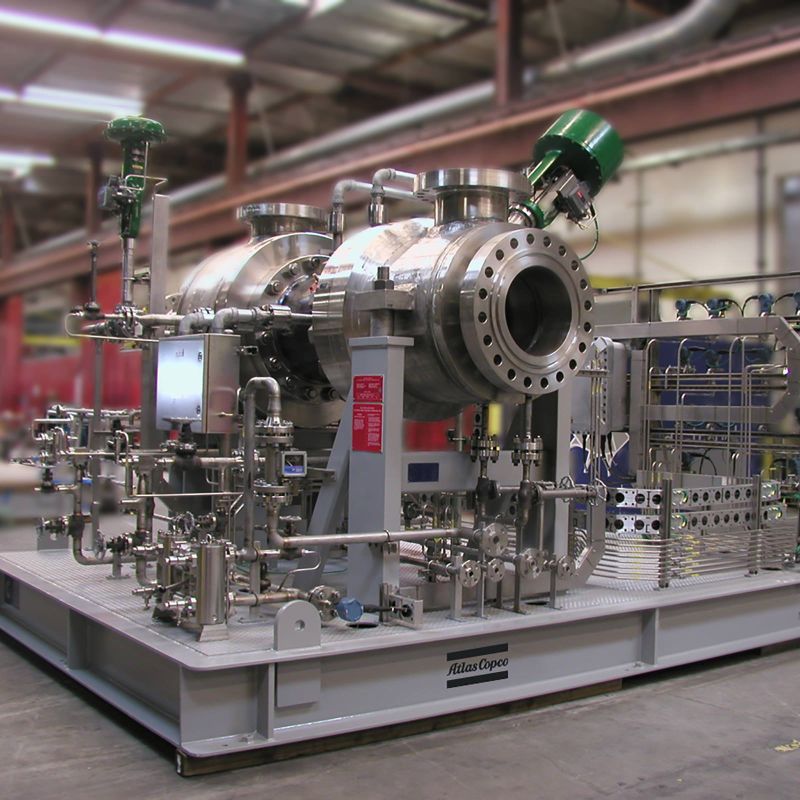

Hyperion Simulation will provide a Stimulated DCS OTS System Solution for the SIPCHEM IGC CO OTS project. A stand alone OTS system will be developed connected to Emerson DeltaV DCS equipment. This solution will provide a hybrid system for the DCS, using emulated controllers and real Emerson DeltaV Operator stations. The Operator’s environment will be replicated using graphics from the actual plant’s DCS. The solution will provide the advanced features of emulated controllers - such as faster-than-real-time performance.

Hyperion Simulation will be the main supplier of the OTS system, and responsible for the functionality and handover of the complete system.

Hyperion Simulation’s responsibilities on the project will include:

* Development of the dynamic process models for the IGC Carbon Monoxide (CO) plant, using DYNSIM™ dynamic simulation software

* Emulation of the Safety System

* Integration of the process models with the emulated Safety System

* Development of the Instructor and Field Operator Station

* Integration of the Emerson DeltaV DCS simulation system with the process models and the Safety System

* Installation and commissioning in an exclusive training facility at SIPCHEM site

* Provision of appropriate training and documentation (manuals and specifications)

Reliability Engineering Department of SIPCHEM stated, “An OTS system is a valuable tool that is mainly used to train control room operators and field operators on various aspects of the plant operations. With this project we expect to receive a custom OTS system, developed to match the SIPCHEM process equipment and provide the same “look and feel” as real features of CO process operation. We have selected Hyperion Simulation for this project, as they have proven experience in the development and delivery of similar systems and we are confident that they can satisfy our expectations and project requirements.”

Mr. Dean R. Jones, Executive Vice President of Hyperion Simulation stated, “We are truly satisfied by the fact that SIPCHEM has selected Hyperion Simulation for the provision of the IGC CO OTS. Hyperion Simulation is committed to develop and deliver a custom OTS system which will provide the trainees with a very realistic representation of the actual process unit at steady state and dynamic conditions, in such a manner that there is no significant difference between operating at the simulator or, the actual process unit. The Hyperion OTS will ensure that SIPCHEM will capture benefits on a year to year basis by using the simulator throughout the plant lifecycle.”

News Category:

-

John Crane unveils Type 8628VL mechanical seal

John Crane has launched the Type 8628VL, a next generation mechanical seal engineered to solve the oil and gas industry's toughest challenges: maintaining sealing integrity ...

09-09-2025

-

Clariant to supply catalyst to the world's largest electric steam methane reformer

Clariant, a sustainability-focused specialty chemical company, today announced a supply agreement with SYPOX to manufacture and deliver catalysts for what will be the ...

09-09-2025

-

Worley receive FEED verification contract for renewable diesel and aviation fuel project

Worley has been awarded a contract by Preem for Front-End Engineering Design (FEED) verification for the planned conversion of the ICR plant at the Lysekil refinery in ...

08-09-2025

-

Honeywell to optimise production at AMIGO LNG export terminal in Mexico

Honeywell today announced that its modular liquefied natural gas pretreatment technology and Integrated Control and Safety Systems (ICSS) will be adopted at AMIGO LNG ...

01-09-2025

-

Covestro selects EnviNOx® technology for its Baytown site

thyssenkrupp Uhde has successfully delivered and commissioned its proprietary EnviNOx® technology to Covestro’s Baytown, Texas, facility. The advanced emission control ...

01-09-2025

-

REZEL Catalysts Corporation, a leading global catalyst manufacturer and licensor, and Aramco, one of the world's leading integrated energy and chemicals companies, announced ...

26-08-2025

-

Wood to provide project management consultancy services on Turkey's largest polypropylene plant

Wood, a global leader in consulting and engineering, is providing project management consultancy (PMC) services to develop Turkey's largest polypropylene plant and associated ...

21-08-2025

-

thyssenkrupp Uhde completes Pre-FEED for the Portland renewable fuels project

thyssenkrupp Uhde has completed the Pre-FEED phase for the Portland Renewable Fuels Project in collaboration with HAMR Energy. The project, located in Victoria, Australia, ...

21-08-2025

-

Accelerating the Demonstration Project for Its New Technology Contributing to the Petrochemical Industry’s Effort to Switch to Alternative Feedstocks Sumitomo ...

20-08-2025

-

Vioneo selects Lummus as its Polypropylene partner for a new grassroots plant in Antwerp

Lummus Technology, a global provider of process technologies and value-driven energy solutions, announced Vioneo has selected its Novolen® polypropylene (PP) technology ...

19-08-2025