31-03-2019

Sinopec successfully starts up largest composite ionic liquid alkylation unit

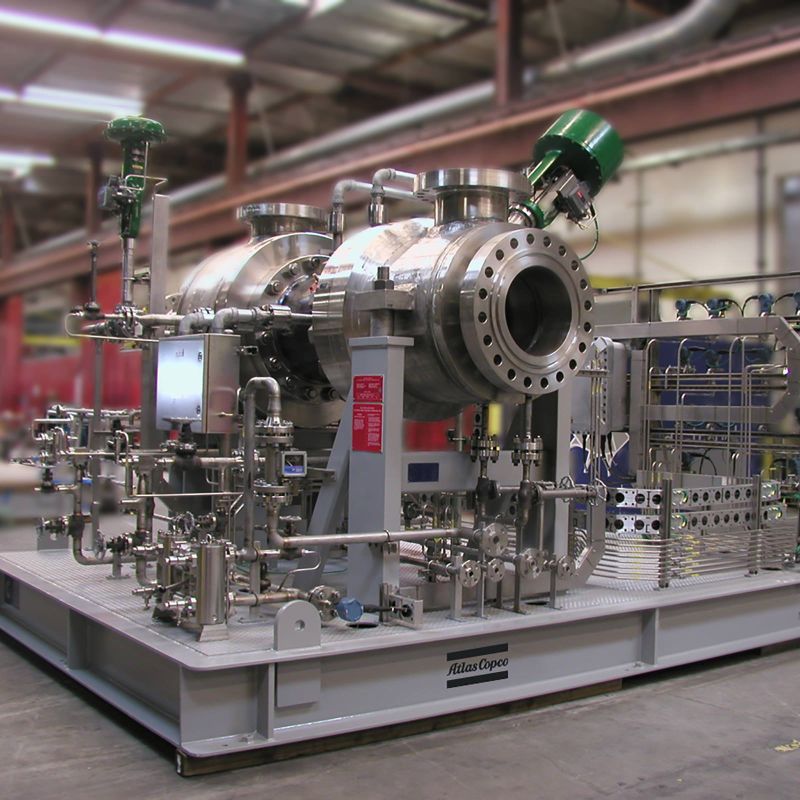

Well Resources Inc. announced the successful start-up of a brownfield Ionikylation unit in Sinopec’s 161,000 barrel-per-day refinery in Jiujiang City, Jiangxi Province. The unit, capable of producing 300,000 tonnes-per-year of high quality alkylate, is the largest commercial adoption of the Ionikylation technology to date. Sinopec is on track to commission two additional Ionikylation units of the same capacity at its Anqing and Wuhan refineries later this year.

The construction of the Ionikylation unit at Sinopec Jiujiang refinery started in February 2018 and completed in December 2018. Unit start-up preparation began in mid-March 2019. On March 31, 2019, the catalyst and feed were introduced into the Ionikylation reactor and subsequently Sinopec reported that the first batch of high-quality alkylate was successfully produced.

Ionikylation is a commercially proven and environmentally friendly alkylation process that uses a proprietary composite ionic liquid as the catalyst. Unlike traditional alkylation processes that use dangerous and hazardous hydrofluoric or sulfuric acid as the catalyst, the Ionikylation catalyst is safe to handle. Ionikylation is a cost-effective option for refiners that are looking to improve the safety of their operations without sacrificing product quality.

News Category:

-

SATORP selects innovative technologies from Veolia

Veolia announces the signing of an agreement between the consortium comprising Veolia, Marafiq, and Lamar, and SATORP (a joint venture between Saudi Aramco and TotalEnergies ...

15-09-2025

-

Coolbrook announces large-scale pilot successfully cracks plastic waste pyrolysis oil

Coolbrook, a transformational technology and engineering company, has achieved a major breakthrough in circular plastics and materials by successfully cracking 100% plastic-waste-derived ...

15-09-2025

-

Burckhardt Compression acquires ACT

On September 12, 2025, Burckhardt Compression completed the acquisition of ACT (Advanced Compressor Technology), a service company specializing in reciprocating equipment ...

12-09-2025

-

TOYO awarded first phase of major overhaul project for large-scale gas chemical complex

Toyo Engineering Corporation, in collaboration with Rönesans Endüstri Tesisleri, a member of Rönesans Holding, a leading global contracting and investment group headquartered ...

11-09-2025

-

Technip Energies acquires advanced materials & catalyst segment from Ecovyst

Ecovyst Inc, a leading integrated and innovative global provider of advanced materials, specialty catalysts, virgin sulfuric acid and sulfuric acid regeneration services ...

11-09-2025

-

Clariant to supply catalyst to the world's largest electric steam methane reformer

Clariant, a sustainability-focused specialty chemical company, today announced a supply agreement with SYPOX to manufacture and deliver catalysts for what will be the ...

09-09-2025

-

John Crane unveils Type 8628VL mechanical seal

John Crane has launched the Type 8628VL, a next generation mechanical seal engineered to solve the oil and gas industry's toughest challenges: maintaining sealing integrity ...

09-09-2025

-

Worley receive FEED verification contract for renewable diesel and aviation fuel project

Worley has been awarded a contract by Preem for Front-End Engineering Design (FEED) verification for the planned conversion of the ICR plant at the Lysekil refinery in ...

08-09-2025

-

Honeywell to optimise production at AMIGO LNG export terminal in Mexico

Honeywell today announced that its modular liquefied natural gas pretreatment technology and Integrated Control and Safety Systems (ICSS) will be adopted at AMIGO LNG ...

01-09-2025

-

Covestro selects EnviNOx® technology for its Baytown site

thyssenkrupp Uhde has successfully delivered and commissioned its proprietary EnviNOx® technology to Covestro’s Baytown, Texas, facility. The advanced emission control ...

01-09-2025