24-05-2022

Integrating carbon capture technology at the Phillips 66 Humber refinery

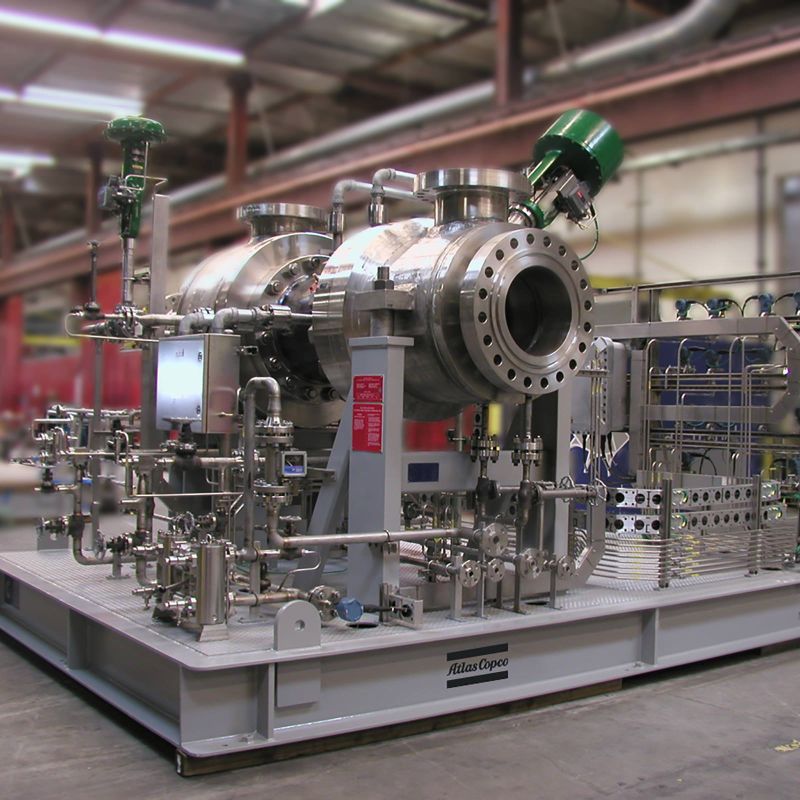

Worley has been awarded the early front-end engineering services for a carbon capture facility at the Phillips 66 Humber Refinery in the UK.

We’ll be working with Phillips 66 Limited to integrate Shell’s carbon capture technology — CANSOLV — into the refinery and design the infrastructure required to export the carbon dioxide (CO2) into the proposed transport and storage network.

“We’ve been working at the Humber Refinery for more than two decades, and we look forward to collaborating with Phillips 66 Limited and Shell on this significant project to reduce carbon dioxide emissions at scale,” said Brad Andrews, President at Worley.

Making sustainable transformation a reality with the Phillips 66 Humber Refinery Currently, the Humber region produces 40 percent of the UK’s industrial carbon emissions. This project supports Humber Zero, a first-of-a-kind project, and puts the Humber Refinery on track to become the first refinery in the world to reduce its carbon emissions using CANSOLV. This could provide a model for decarbonizing refineries and make a significant impact on the UK’s net-zero ambitions.

CANSOLV will be deployed to capture carbon produced in the refinery’s fluid catalytic cracking (FCC) process. The technology has the potential to capture at least 95 percent of the CO2 in the FCC flue gas, compressing it before the gas is transported to be safely stored under the North Sea <https://www.worley.com/our-work/northsea> .

Humber Refinery General Manager Darren Cunningham, the Lead Executive for Phillips 66 in the UK, described the project as “hugely significant” from a technology perspective.

“There are more than 300 FCCs in the world,” Cunningham said. “We would be developing technology that has the potential to decarbonize them. “We’re looking forward to working with the Shell team, which brings a huge amount of carbon capture experience to the table, and with Worley, delivering this important project to the region.”

“This project is aligned with Worley’s focus and investment in capability to help decarbonize existing industrial assets in the UK and our purpose in delivering a more sustainable world,” said Andrews.

The projected start-up of the facility is expected in 2027.

News Category:

-

John Crane unveils Type 8628VL mechanical seal

John Crane has launched the Type 8628VL, a next generation mechanical seal engineered to solve the oil and gas industry's toughest challenges: maintaining sealing integrity ...

09-09-2025

-

Clariant to supply catalyst to the world's largest electric steam methane reformer

Clariant, a sustainability-focused specialty chemical company, today announced a supply agreement with SYPOX to manufacture and deliver catalysts for what will be the ...

09-09-2025

-

Worley receive FEED verification contract for renewable diesel and aviation fuel project

Worley has been awarded a contract by Preem for Front-End Engineering Design (FEED) verification for the planned conversion of the ICR plant at the Lysekil refinery in ...

08-09-2025

-

Honeywell to optimise production at AMIGO LNG export terminal in Mexico

Honeywell today announced that its modular liquefied natural gas pretreatment technology and Integrated Control and Safety Systems (ICSS) will be adopted at AMIGO LNG ...

01-09-2025

-

Covestro selects EnviNOx® technology for its Baytown site

thyssenkrupp Uhde has successfully delivered and commissioned its proprietary EnviNOx® technology to Covestro’s Baytown, Texas, facility. The advanced emission control ...

01-09-2025

-

REZEL Catalysts Corporation, a leading global catalyst manufacturer and licensor, and Aramco, one of the world's leading integrated energy and chemicals companies, announced ...

26-08-2025

-

Wood to provide project management consultancy services on Turkey's largest polypropylene plant

Wood, a global leader in consulting and engineering, is providing project management consultancy (PMC) services to develop Turkey's largest polypropylene plant and associated ...

21-08-2025

-

thyssenkrupp Uhde completes Pre-FEED for the Portland renewable fuels project

thyssenkrupp Uhde has completed the Pre-FEED phase for the Portland Renewable Fuels Project in collaboration with HAMR Energy. The project, located in Victoria, Australia, ...

21-08-2025

-

Accelerating the Demonstration Project for Its New Technology Contributing to the Petrochemical Industry’s Effort to Switch to Alternative Feedstocks Sumitomo ...

20-08-2025

-

Vioneo selects Lummus as its Polypropylene partner for a new grassroots plant in Antwerp

Lummus Technology, a global provider of process technologies and value-driven energy solutions, announced Vioneo has selected its Novolen® polypropylene (PP) technology ...

19-08-2025