Question

-

WAO unit: In spite of pH control of spent caustic (7 to 9 pH) corrosion happening(@rate1.6mm/year) in WAO unit after neutralization of spent caustic with sulfuric acid circuit. Is similar case available in any of WAO unit and what could be the possible reason, What kind of mitigation used to control the corrosion?

Jul-2025

Answers

-

SRIDHAR BALAKRISHNAN, Bharat Oman Refinery Limited , laksrid@yahoo.com

Corrosion in WAO neutralisation circuits can still occur even when the pH is maintained between 7 and 9, due to several interacting factors. Poor mixing of sulfuric acid during neutralization may create temporary low-pH areas (below 4) near the injection points, leading to localised acid attack on the metal. Spent caustic often contains sulfur compounds like sulfides, thiosulfates, sulfites, or polythionates, which become highly corrosive to carbon steel after partial oxidation, especially at near-neutral pH. High operating temperatures (120–250°C) increase the corrosion rate, and residual dissolved oxygen can further speed up metal oxidation. Additionally, even small amounts of chlorides (less than 50 ppm) can cause pitting or under-deposit corrosion. If carbon steel or low-alloy steel is used, the risk of corrosion is much higher under these conditions.

Aug-2025

-

Marcio Wagner da Silva, Petrobras, marciows@petrobras.com.br

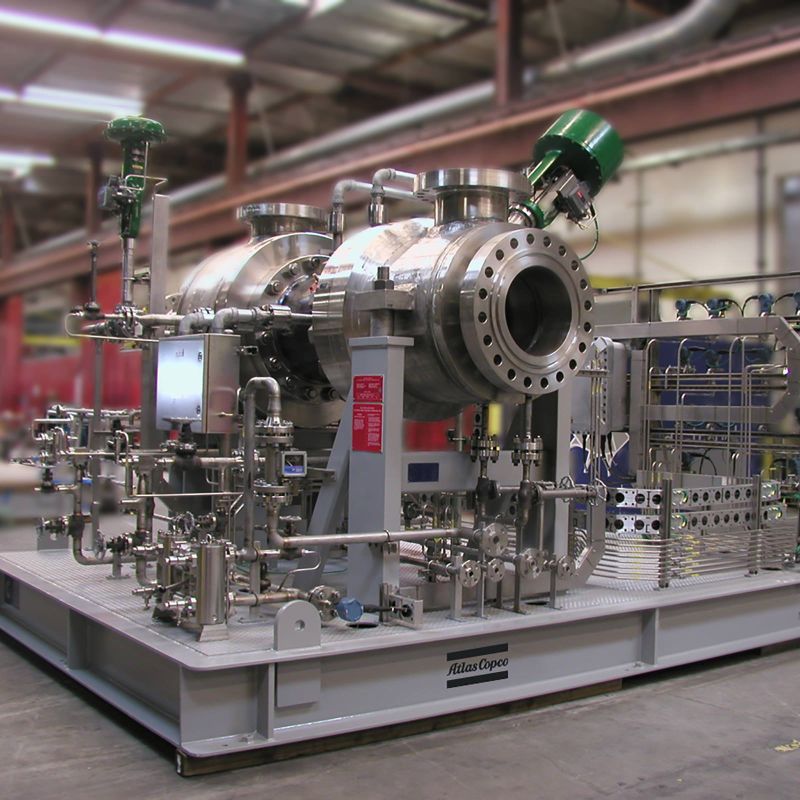

Wet Air Oxidation (WAO) process is normally applied to treat caustic waste in processing plants like ethylene production plants and crude oil refineries to treat LPG in delayed coking and FCC processing units. Considering the information available in the question, the pH variable is under control despite some references quote that keeping the pH post neutralization section over 8 can avoid the formation of acidic gases in the process. To reach an adequate diagnostic is important to understand the corrosion mechanism which leads to this relatively high corrosion rate as well as good characterization of the feed to verify if the contaminants content like hydrocarbons, sulphur, chloride and caustic concentrations are according to the process unit design. If the processing unit applies seawater as cooling or process fluid, the chloride concentration can be a serious issue. WAO can suffer with corrosion issues under certain conditions like high sulphur concentration, high temperatures also can accelerate the corrosion rates as well as the production of naphthenic acids during the process caused by high concentration of hydrocarbons in the feed and high temperature operation. As mitigation strategies can be applied optimization strategies, when possible, like to reduce the operating temperature. Applying noblest metallurgy like nickel alloys can be another good strategy as well as to apply corrosion inhibitors, again it's fundamental to understand the main corrosion mechanism to define the adequate corrosion control strategy.

Jul-2025