Jan-2011

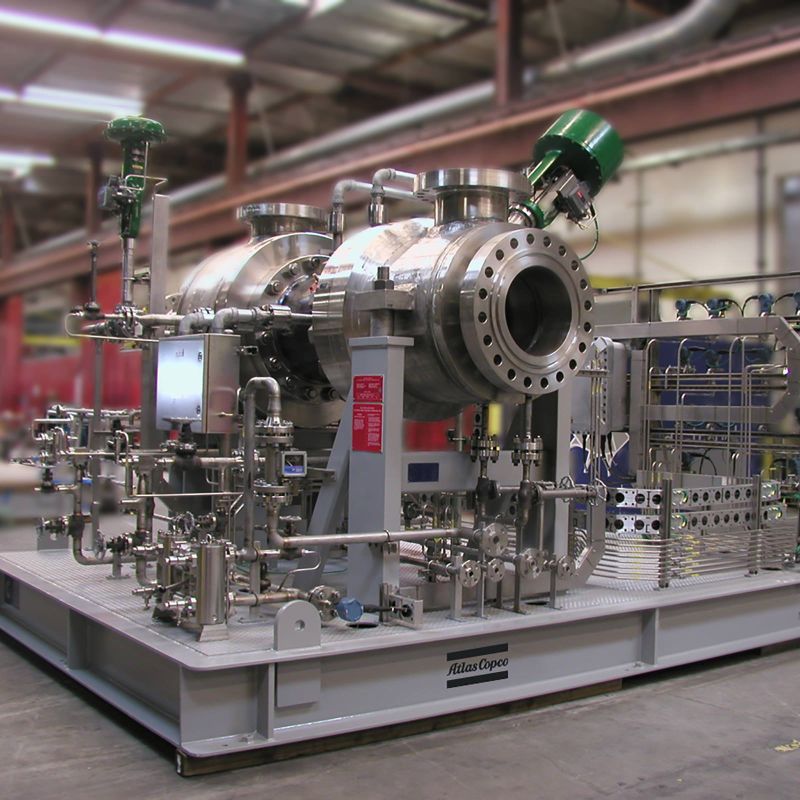

Elemental Analysis in waste oil and recycling

Huge quantities of waste oil and related wastes are generated each year. Properly collected and processed, these wastes can be a valuable energy source or be refined to produce usable products such as new lubricating oil.

Olaf Schulz

SPECTRO Analytical Instruments

Viewed : 10826

Article Summary

However waste oil is usually contaminated, because of its previous use, with water and other liquids, halogens and other elements including heavy metals. In most countries it is regarded as potentially hazardous waste and must be handled, processed and stored appropriately. Its transport, storage and ultimate uses are governed by a variety of direct and indirect national and international legislation and industry standards. A worldwide specialist industry has developed to collect, transport and process waste oil and to market the products derived from it.

Elemental analysis is an essential part of the environmental protection and quality control procedures associated with the recycling of waste oil. The two analytical techniques most frequently used for elemental analysis in this industry are Energy Dispersive X-ray Fluorescence (EDXRF) spectrometry and Inductively Coupled Plasma — Optical Emission Spectrometry (ICP-OES). This paper describes these techniques and how the range of instruments from Spectro Analytical Instruments meet the current and future requirements for elemental analysis in the waste oil recycling industry.

Waste oil: origins, uses and legislation

Although a major source of waste oil is used automotive lubricants, the oil recycling industry has developed so that a wide variety of wastes are treated to produce usable product. A proposed UK Quality Protocol lists over 80 different waste classifications that are acceptable as inputs for processing to manufacture processed fuel oil, or PFO. These can be as diverse as paint wastes and drilling muds, and of course include the more common materials such as waste engine and gear oils, hydraulic fluids and machining fluids.

The quantities involved are considerable. The EU consumes around 5 million tons of base oils a year, of which roughly half becomes waste in due course. The remainder is consumed in use and lost due to spillage etc. Similarly in the US, about half the annual demand of around 2.5 billion gallons becomes waste.

There are a number of legally approved routes for the disposal of waste oil, each subject to legislation. Regulations are being reviewed continually, and some of these uses may become restricted as legislation changes. The main legal disposal routes are:

• Direct combustion/use as fuel

• Processing to produce secondary fuels

• Re-refining to produce new base oil and other petroleum products.

The routes chosen in different countries vary greatly and depend on factors such as local energy policies, customs tariffs and the like. Of the waste oil produced, approximately half is used as fuel. Re-refining involves significant investment in plant and in some countries a premium price for the product. Currently some countries are claiming re-refining rates of over 70% of waste oil collected while others are close to zero. A significant proportion of waste oil is burned or otherwise disposed of illegally: up to a quarter of all lubricating oil produced is disposed of in this way.

Direct combustion/use as fuel

Examples of plants that may be approved to burn waste oils include cement works, steelworks and waste incinerators. In the EU, this use is covered by the Waste Incineration Directive, which sets limits on the emissions to air of substances generated during such combustion, and on emissions to water and any slag or ash generated. Indeed, any slag or ash produced may itself be classified as hazardous waste and be subject to its own disposal controls. Because these emissions will depend on the design of the combustion system, such plants are usually licensed individually and are subject to routine monitoring and environmental audits to ensure that emission limits are met. Clearly it will be necessary to ensure that inputs to these plants remain within the limits of impurities that the design can handle, so it is usually necessary to use known sources or to analyse the waste on receipt. Co-incineration, when mixtures of combustible wastes are burned together, is a common practice and can mean that heavily contaminated material can be “diluted” with cleaner waste to keep emissions within limits. Waste oil can also be burned in space heaters and so-called small waste oil burners (SWOBs) and is used as a heat source in processing roadstone and asphalt. All these uses are subject to licensing and emission limits.

Processing to produce secondary fuels

These fuels are known variously as recovered fuel oil (RFO) or processed fuel oil (PFO). Until recently processing has involved basic clean-up such as dewatering and processes such as filtering, settling or centrifuging to remove solid contaminants. RFO has been in use for many years and various commercial specifications apply, with limits on elements such as sulphur, halogens, nickel, vanadium and sodium. More recently, environmental concerns have led to proposals for tighter controls on recovered fuels. In the US, waste oil and recovered fuels will be categorised as either “on-spec” or “off-spec”. The EPA considers that only certain contaminants in used oil pose a significant threat to human health or the environment and has established maximum concentration limits for the contaminants shown in Table 1. Waste oil or RFO with less than these concentrations is on-spec and can be burned in any combustion device. Off-spec RFO is regarded as waste and must be treated accordingly. Waste oil containing more than 4000 ppm of total halogens it is classified as hazardous waste and must be disposed of at a facility designated for that purpose. The same distinction between waste and commodity is found in a Quality Protocol published by UK government agencies. This gives specifications for levels of heavy metals and other contaminants in fuels that can be used as direct substitutes for two existing grades of fuel, gas oil and heavy fuel oil, described in British Standard BS2869:2006 as Class D and Class G, respectively. Recovered fuels meeting these specifications may be burned without restrictions (see Table 2).

Re-refining

These limits, if adopted, will place new demands on the processing and analytical resources of oil recycling companies. As mentioned above, the proportion of waste oil that is re-refined varies widely from country to country. After initial clean-up of the waste re-refining oil, re-refining uses the same basic techniques that are used in crude oil refining, namely distillation, hydrotreatment and various finishing processes. It should be remembered that oil does not lose its basic lubricating properties in use, but suffers from fuel dilution, additive depletion and contamination by soot and other combustion by-products and wear metals. The objective of re-refining is to recover the base oils that can then be blended with additives to produce new lubricating oils. Compared with other disposal routes, re-refining involves considerable capital cost and unless favourably treated by local tax regimes can be more expensive than lubricating oil derived from crude. It is however claimed that re-refining yields energy benefits compared to the refining of new crude oil and generates less pollution than burning the waste as fuel. These factors combined with volatile oil prices and a desire by many countries to reduce dependence on imported oil suggest that re-refining may become a more popular disposal route in the future. Furthermore, in the EU, the new Waste Framework Directive, 2008/98/EC, will allow member states that stipulate re-refining as the preferred disposal route to prevent the export of waste oils for incineration elsewhere. The disposal routes described above will all have different analytical requirements. Most will require a screening technique to avoid waste oil being accepted for treatment that is contaminated to a degree that is beyond the capacity of the treatment plant to remove or may lead to emission limits being exceeded in the case of incinerators. Toxic elements can be concentrated in incinerator ash, so this may need to be analysed too. Those producing secondary fuels will also need to demonstrate that these fuels meet the increasingly strict limits on heavy metals and halogens. Re-refining plants that produce finished lubricants may also need to determine additive concentrations as part of their quality control procedures. Typical concentration levels for contaminants lie in the range from 1 to 500 parts per million, and some additive elements can be at several thousand ppm. For most elements, these concentrations are well within the scope of spectroscopic techniques such as EDXRF and ICP-OES. The choice of technique will depend on the ultimate performance required. EDXRF will be ideal for screening applications and the determination of most additives. In markets where the newer, more demanding limits are imposed, it may be necessary to employ the higher sensitivities of ICP-OES for the analysis of recovered fuels. In any case, the sensitivity required for screening applications will usually be considerably less than that required to demonstrate product conformity. The conventional way of expressing an instrument’s ultimate ability to detect a given element is limit of detection (LOD), but perhaps a more useful guide is limit of quantitation (LOQ) as it represents the lowest concentration that can be reliably measured. Examples of LOD and LOQ in oil matrices are given below for various instruments. Both techniques can be used when sample numbers are relatively small, but when high sample throughput is required, the relatively high speed of simultaneous ICP-OES has made it the technique of choice in service laboratories. The requirement for speed and the need to measure many elements in each sample means that sequential techniques like atomic absorption spectrometry (AAS) and sequential ICP-OES are usually considered too slow for high throughput applications. When analysing raw untreated waste, its heterogeneous nature can give rise to significant sampling errors. Some wastes may contain separate phases and this needs to be taken into account in sampling procedures.

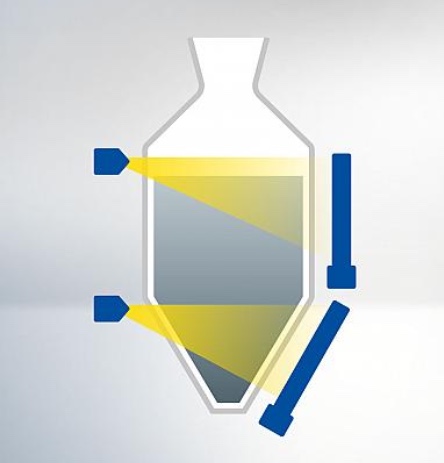

edXrf - basic principles

The technique works by irradiating the sample with a beam of X-rays to induce fluorescence in the atoms in the sample, which is then emitted as X-rays of a lower energy. Each element emits fluorescent X-rays of different and unique energies or wavelengths, whose intensity is proportional to the concentration of that element in the sample. X-ray detection systems have been developed that can themselves discriminate between the X-ray energies emitted, measure their intensities and hence determine the concentration of the different elements in the sample. This technology is known as energy dispersive X-ray fluorescence, or EDXRF. A more recent development in EDXRF has been the advent of instruments that polarise the X-radiation before it impinges on the sample. This is done by reflecting the X-ray beam from a suitable target, usually a specially prepared and shaped crystal.

Add your rating:

Current Rating: 4