Dec-2019

Preventing yellow metal corrosion

A novel corrosion inhibitor for yellow metal meets corrosion and environmental targets under halogen control.

DANIEL MEIER and RENATE RUITENBERG

Nalco Champion, an Ecolab Company

Viewed : 6271

Article Summary

Yellow metal heat exchangers are widely used in the most critical unit operations of refineries and petrochemical plants due to their high thermal conductivity and antifouling properties. However, copper and its alloys such as admiralty brass suffer from corrosion in acidic to neutral and highly halogenated environments that are common in cooling water systems. This may result in reduced life and subsequent failure of heat exchangers resulting in loss of production and downtime for replacement.

In the last few decades, different triazole chemistries were used as a protective filming inhibitor for yellow metal.1 These chemistries have their limitations, including poor stability in halogenated environments, high consumption rates, and high aquatic toxicity. This article presents an innovative non-triazole based yellow metal corrosion inhibitor with improved halogen stability, lower consumption rates, and reduced aquatic toxicity compared to traditional triazole compounds.

The patent-pending chemistry has been evaluated for its performance in electrochemical tests, pilot cooling tower tests, and customer field trials. The results from both lab and field trial are discussed in detail.

Yellow metal corrosion

Refineries and petrochemical plants utilise yellow metal heat exchangers in their most critical unit operations due to their high thermal conductivity. While the antifouling properties tend to limit microbial under-deposit corrosion, copper and alloys such as admiralty brass are still vulnerable to corrosion due to the chemical composition of cooling water and excessive halogen attack. Particularly in poor water conditions, chemical corrosion in highly halogenated environments is common in cooling water systems.2 This may result in high maintenance costs due to retubing or replacement of heat exchangers and consequent loss of production and downtime for replacement.

The main corrosion stress factors for yellow metal are:

• Halogenation for biofouling control

• Process control causing pH dips

• High chloride and sulphate levels

• Ammonia from recycled municipal effluent

• High holding time index.

These stress factors are becoming more prevalent, with the challenges of global water scarcity driving the industry towards cooling tower operation at minimal water footprint. Running at high cycles and using recycle water increases corrosion stress in yellow metal.

The challenge is to develop a protective filming inhibitor for yellow metal that is stable under the aggressive cooling water conditions encountered in industry, without being harmful or toxic to aquatic life, a problem raised by traditional triazoles.

Development process

Rigorous literature study identified the potential group of chemistries that could meet the need of a halogenation stable inhibitor which could be classified non-toxic to aquatic organisms. Over 400 molecules were synthesised in the search for a feasible solution. The top candidates were produced in small volumes to allow evaluation on bench top and advanced laboratory pilot cooling tower testing. These samples were sent to various corporate R&D labs around the globe, enabling evaluation in tandem at pilot scale. The best performing inhibitor was one named 3DT397; for this, the manufacturing route was refined.

Laboratory evaluation

Initial laboratory corrosion screening tests were conducted using a Gamry electrochemical system to detect the corrosion rate of copper and brass coupons based on linear polarisation resistance.3 All of the 48-hour tests were carried out in a set water chemistry condition, with 2.5 ppm active inhibitor dosage (3DT397, TT = Tolyltriazole, BZT = Benzotriazole). The pH, temperature, and oxidation reduction potential were controlled, the latter to 0.6 +/-0.15 ppm free residual chlorine. An average corrosion rate of 24-48 hours was calculated at the end of the test. The test results are summarised in Table 1.

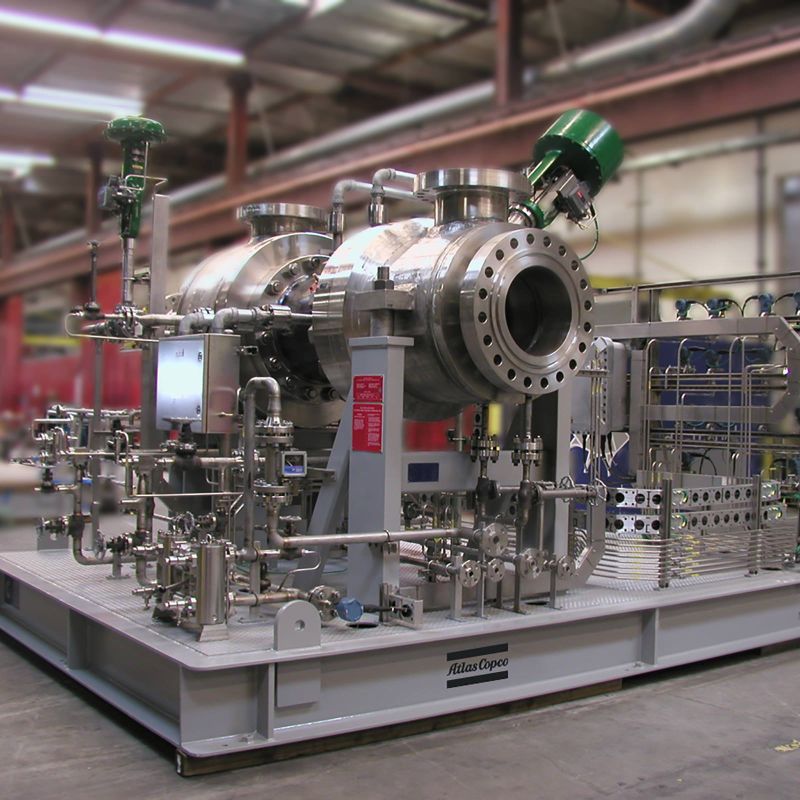

Pilot cooling tower trials were run in Nalco’s R&D laboratories. The trials involved 90l system volume and 50 hours holding time index, operated under 3D TRASAR control at 0.5 mg/l free residual chlorine. Corrosion was measured by weighing the heat transfer tubes and unheated coupons as well as online using corrosion probes. Figure 1 shows the pilot cooling tower results generated for admiralty brass.

The corrosion results show that the new 3DT397 is delivering improved yellow metal corrosion protection. The different corrosion evaluation methods show different corrosion values. The new inhibitor shows consistent low corrosion rates for copper as well (see Figure 2).

Industrial cooling results

Industrial cooling system dynamics increase the stresses associated with corrosion inhibition, for instance long holding time indexes, variable pH, and free residual chlorine control, or challenging make-up water chemistries. Therefore, performance in industrial cooling towers would validate the efficacy of the new inhibitor.

Nalco Champion’s manufacturing plants produced sufficient volumes to introduce 3DT397 to four refineries and chemical plants for industrial cooling trials. All of these trials were in challenging systems with high corrosion stress, looking for improved yellow corrosion inhibition.

Interestingly, the industrial performance of the novel inhibitor is better than was to be expected from bench top and pilot cooling tower trials. Robust performance was the most critical factor in performance, as corrosion stress is higher in industrial systems. One chemical plant was running at 15 days’ holding time, while the other used soft water at up to 10 cycles of concentration. The refineries faced challenges due to highly variable chlorination control (see Table 2).

Regulatory testing confirmed that, in contrast to triazoles, the new chemical is not classified as toxic to the aquatic environment. No chlorinated compounds were found in recirculating cooling water due to low reactivity with the bleach or chlorine gas typically used to disinfect cooling towers.

Add your rating:

Current Rating: 3